Introduction

Tapping is one of the most crucial operations in metalworking and manufacturing. Whether it’s producing internal threads for automotive parts, machinery, or general engineering jobs, taps play a central role. In this blog, we’ll start with the basics of taps, explore key innovations in hand and machine taps, and finally dive into the top five brands dominating the Indian market. If you’re in the business of precision threading, this is your go-to guide.

What is a Tap?

A tap is a cutting tool designed to create internal screw threads inside a drilled hole. This operation is called tapping. The drilled hole is slightly smaller than the required thread size, and the tap cuts (or forms) the threads so that a bolt or screw can fit snugly.

Taps can be used in two main ways:

- By Hand: Using a tap wrench, ideal for repair and low-volume work.

- By Machine: Using CNC machines, tapping heads, or automatic tapping machines for high-volume, precision production.

Hand Taps vs Machine Taps

| Feature | Hand Taps | Machine Taps |

| Usage | Manual threading with a wrench | Automated threading in CNC/tapping machines |

| Common Types | Taper, Plug, Bottoming | Spiral Point, Spiral Flute, Forming taps |

| Speed | Slower, requires operator skill | Faster, consistent, designed for production |

| Chip Control | Less advanced |

Optimized for chip evacuation |

Hand taps are versatile and available in sets (taper, plug, and bottoming). Machine taps are engineered for speed, chip control, and repeatability in industrial setups.

Types of Taps and Their Applications

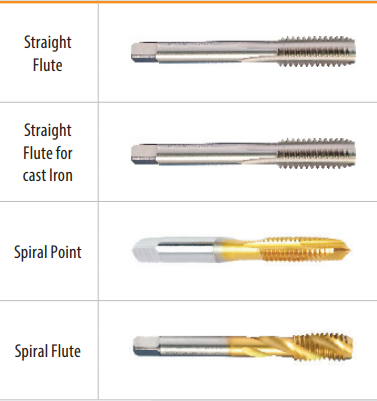

1. Straight Flute Taps

- Simple design, economical.

- Common in hand tapping and basic applications.

2. Spiral Point (Gun) Taps

- Push chips forward.

- Best for through holes in production tapping.

3. Spiral Flute Taps

- Pull chips out of the hole.

- Ideal for blind holes where chips need evacuation.

4. Thread Forming (Roll) Taps

- Do not cut, but form threads by displacing material.

- Produce stronger threads with no chips.

- Great for ductile materials like aluminum or soft steels.

5. Solid Carbide Taps

- High-speed tapping in hard materials.

- Longer tool life, excellent finish, but brittle.

Key Geometry Elements

- Flutes: Carry away chips; 2–4 flutes are standard.

- Helix Angle: Higher angles improve chip removal in softer materials.

- Chamfer (Lead): Defines starting threads. Longer chamfers for taper taps, shorter for bottoming taps.

- Pitch: Determines the thread spacing; affects drill size selection.

Innovations in Tapping

Modern tapping has gone far beyond traditional hand taps. Key innovations include:

- Spiral Geometries: Spiral flute and spiral point taps with variable helix reduce chatter and improve chip evacuation.

- Thread Forming Taps: Chipless tapping with stronger threads, widely used in automotive and electronics.

- Coatings: TiN, TiCN, and TiAlN coatings enhance wear resistance and enable higher speeds.

- Coolant-Fed Taps: Through-coolant designs improve chip flushing and extend tool life.

- Rigid Tapping Cycles: CNC synchronization prevents tap breakage and increases accuracy.

Choosing the Right Tap

| Factor | Recommendation |

| Hole Type | Spiral point for through holes, Spiral flute for blind holes |

| Material | HSS for general use, Carbide for hard materials |

| Coating | TiCN for stainless, TiAlN for high-temp alloys |

| Volume | Hand taps for small jobs, Machine taps for high-volume production |

| Chip Control | Forming taps for chip-free threading |

Pro Tip: Always use the correct tap drill size (usually major diameter – pitch in metric threads) to ensure proper thread percentage and tool life.

Top 5 Tap Brands in India

1. ITM (Indian Tool Manufacturers)

- Part of Birla Precision group.

- Strong presence with HSS and carbide taps.

- Known for affordability and domestic availability.

2. Addison

- Established Indian brand since the 1950s.

- Comprehensive range of taps and cutting tools.

- Strong distribution across India.

3. Miranda

- Classic Indian brand, now under Dormer Pramet.

- Renowned for HSS taps and round cutting tools.

- Widely trusted in the Indian engineering sector.

4. Totem (Forbes Precision Tools)

- Specializes in HSS and carbide round tools.

- Strong local manufacturing and competitive pricing.

- A reliable choice for workshops and SMEs.

5. YG-1

- Korean multinational with global reputation.

- Offers advanced carbide and coated taps.

- Strong presence in India with local facilities in Bengaluru/Tumakuru.

Quick Visual Reference

Conclusion

From simple hand taps to advanced coolant-fed carbide taps, tapping technology has evolved to meet the demands of modern manufacturing. India’s market is well-served by both domestic players (Addison, ITM, Totem) and global distributors (Miranda, YG-1).

If you’re looking for the right tapping solution, connect with Smith International or visit smithtools.co.in. As one of the largest cutting tools distributor and dealer for taps in India, we work closely with Addison, Miranda, and ITM. Our team can even bring in engineers from these manufacturers to support special-purpose jobs that require high-throughput tapping.